NEXCOM Works with IBM To Harness Big Data in Industrial IoT Applications

NEXCOM has collaborated with IBM to help manufacturers delve into big data using analytic applications in the cloud. Sweeping the industrial and manufacturing sector, the big data is catalyzing the convergence of operational technology (OT) and information technology (IT). In response to the momentous wave of digital transformation, the collaboration between NEXCOM and IBM is aimed to facilitate the use of big data harnessed from industrial IoT to allow for more data-driven decision-making.

The industrial and manufacturing sector sees big data as a tool to increase efficiency, reduce cost and waste, and explore new business models. As different clients have different agendas, it requires a configurable IoT gateway solution with flexibility in from data acquisition to data analysis to quickly respond to all clients’ needs. This is the essence of IBM and NEXCOM collaboration.

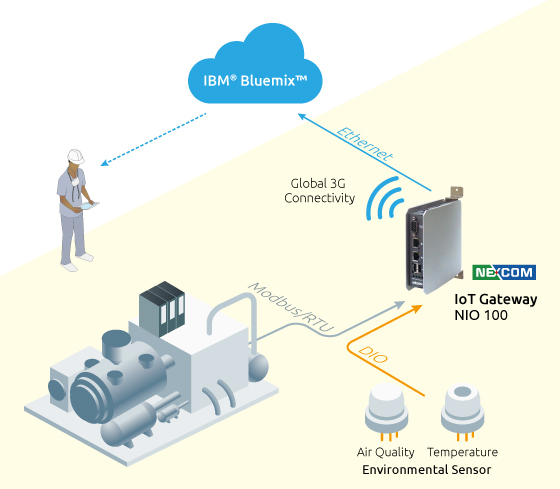

“With expertise in industrial network communication, NEXCOM have broken barriers to multi-protocol data acquisition from a plethora of manufacturing equipment and field devices while leveraging IBM® Bluemix™ enables NEXCOM to create the Connect-to-Cloud (C2C) software engine with ease. For the purposes of data analytics, archiving and others, the C2C software engine—built with Node-RED along with APIs on IBM Bluemix—employs the “software-defined data path” method for provisioning and configuring connections between edge devices and cloud applications,” said YC Cheng, Assistant Vice President of NEXCOM’s IoT Automation Solutions Group.

IBM Bluemix is the cloud platform that helps developers rapidly build, manage and run web and mobile applications. IBM Bluemix enables developers to build and deploy new applications, embrace development and operations and extend existing IT investments with cloud integration services.

Under the partnership, NEXCOM has developed the NIO 100 series in which industrial IoT, big data, and cloud services come together as a cloud-ready IoT gateway solution. The solution provides a web-based user interface for not only software-defined data path but also remote asset management. With a few clicks, drags, and drops, manufacturing machine vendors can start managing on-site machines, processing field data, and handling local events, making possible predictive maintenance for instance. End users such as factory operators can benefit from the reduction in unexpected operation interruption.

“NEXCOM has a worldwide client base. Working with a global technology service company like IBM brings several gains,” added Cheng. “IBM’s broad domain knowledge and datacenters around the globe are as important factors as massive development support to NEXCOM.”

- Related Links:

- NEXCOM and Stereolabs announce collaboration to deliver AI Vision solutions for Mobility, Robotics and Industrial Markets

- NEXCOM Joins NVIDIA Halos AI Systems Inspection Lab

- Browse Other News:

- NEXCOM to Unveil "Embodied AI Robots - Safe by Design" at NVIDIA GTC 2026

- Surge Immunity by Design: EMC Strategies for IEC 61850/IEEE 1613 Network Gateways

- All Corporate News