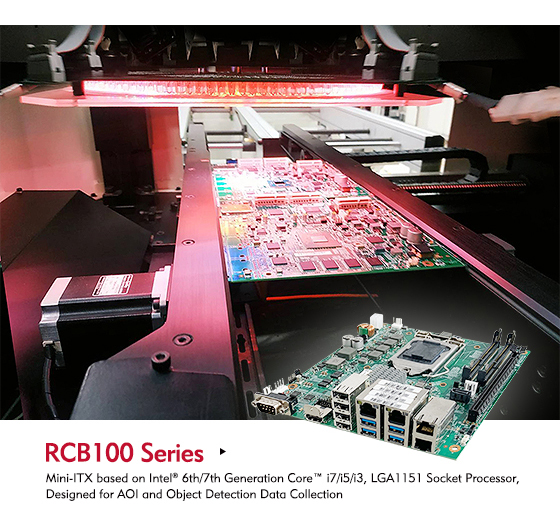

The Perfect Robot and Machine Companion: the RCB Series

Emphasizing scalability and segmentation, NexCOBOT brings you the RCB Series, a series of embedded boards specifically focused on robotic and machine control and data collection. Depending on your production line’s requirements, you can choose between two variants, RCB 100 for robotic/machine control and RCB 100-L4 for data collection. Both include a rich array of I/Os condensed onto one panel for easy access. In particular, the RCB 100-L4 connects effortlessly to robotics-related devices such as controllers, I/O boards, and IP cameras, making it especially suitable for automated optical inspection (AOI), object detection, and logistics operations uses.

|

|---|

Separate uses but equally important

The RCB Series is small-scale, so that when you encounter production line issues, you can easily access and maintain the embedded board without disassembling it, allowing you to bring your systems back online quickly. Secondly, each individual device experiences better performance. Instead of multiple computers sharing processing power, each individual computer processes its own load and consequently lightens the system’s total load, increasing efficiency immediately and productivity over the long term.

Maximize the capabilities of the RCB 100

The RCB 100 provides tremendous functionality as a controller. The rich array of I/Os includes two Intel® I210 LAN ports for EtherCAT communication, a VGA port to link to teach pendant, two internal USB ports for software license dongles, and additional isolated digital I/O. It also comes with mini-PCIe expansion for fieldbus master communication modules, encompassing protocols such as PROFINET, PROFIBUS, DeviceNet, EtherNet/IP, CANopen, and SERCOS III.

Orderly I/Os for AOI/object detection and logistics

The RCB 100-L4 embedded board is particularly appropriate for AOI and object detection data collection, particularly in semiconductor, LED, solar, textile, automobile, and pharmaceutical component production. All I/Os are easily accessible for effortless connections to other robotic control devices, avoiding cable tangles. The four LAN ports can link to cameras to capture images and collect data.

With the ongoing coronavirus pandemic, logistics operations have needed to quickly switch from human labor to automation and adapt supply chains accordingly. This is where RCB 100-L4 becomes especially critical as the link between machine vision and equipment. For instance, package sorting lines can use each of six USB or any of the aforementioned LAN ports to capture images of each package side for more efficient processing.

Main Features

- Intel® 6th/7th Generation Core™ i7/i5/i3, LGA1151 socket processor, max. 65WTDPs, LGA1511, H110

- Supports two DDR4 SO-DIMM socket

- Supports dual display HDMI and VGA

- 4 x Intel® GbE LAN ports (2 x ECAT)

- 4 x USB 3.1 (Gen1), 4 x USB 2.0, 1 x RS232/485/422, 1 x SATAIII, onboard isolated I/O

- 1 x PCIe x16, 1 x mini-PCIe

- 1 x 2x2 4P ATX-12V connector, DC24V in

Ordering Information

RCB100 (P/N: 10J200RCB00X0)

Robot control board, equips with rich I/Os for robot control application and comes with isolated digital I/O for multiple usages and PoE port to connect to industrial cameras

RCB100-L4 (P/N: 10J200RCB07X0)

Mini-ITX based on Intel® 6th/7th Generation Core™ i7/i5/i3, LGA1151 socket processor, designed for AOI and object detection data collection

- Related Links:

- NexAIoT Tech Day – Digitalization and Safety Robots Innovate Green Manufacturing

- NexCOBOT’s SRB, Your Ultimate UR+ Robot Gateway Integrator

- Browse Other News:

- NEXCOM to Unveil "Embodied AI Robots - Safe by Design" at NVIDIA GTC 2026

- Surge Immunity by Design: EMC Strategies for IEC 61850/IEEE 1613 Network Gateways

- All Products News