XPPC 16-100 Panel PC Powers Food Production Data Collection

Introduction

Timely and accurate data-driven decision-making hinges on collecting the information that is most important for making informed choices. Production lines are complex systems that typically run continuously to avoid the cost of system downtime. Keeping track of items as they progress through the various processes is a key ingredient in ensuring that the right items get to the right places at the right time.

Our customer, a food processing factory in Poland, wanted an all-in-one panel PC to implement a barcode scanning system along their production line that would trigger when a product arrived, scan the product barcode, then transmit the data to the backend systems.

They used the XPPC 16-100 industrial panel PC with Intel® Celeron® CPU for this application. The XPPC 16-100 is a slim computer designed for harsh industrial production environments with various mounting options for easy integration, efficient and uncompromising design, and I/O ports that meet the needs of typical industrial applications.

Easy Mounting in Clean, Stainless Steel Enclosure

Keeping facilities clean is a primary concern for food production, with health and safety regulations setting the expectations. For integrators, this means installing the XPPC 16-100 in an easy-to-clean stainless steel enclosure. The versatile mounting options enabled our customer to quickly and easily install the XPPC 16-100 in the stainless steel enclosure, leaving the touchscreen computer front panel exposed to the elements.

Rugged Design to Operate in Harsh Environments

Dust and regular wet cleaning pose a challenge to most computers. The XPPC 16-100 front panel is IP65 compliant, so it has been tested against the ingress of water and dust, protecting it from environmental dust and the water used during regular cleaning. The stainless steel enclosure protects the back, so it is well protected and easy to wipe down.

Full Customization

Great products need great branding, and that brand consistency runs through every detail of the product. To give the customer full control over their branding, the BIOS is set to show the customer’s logo and branding, showing their own logo right from the time the mirror therapy system is turned on. Beyond hardware considerations, this small step is the icing on the cake that transforms a potentially “hack” retrofit into a fully integrated, seamless system. On top of that, NEXCOM offers a wide range of flexible services to customize many different aspects of the hardware.

The Essential System for Production Line Automation

The NEXCOM XPPC 16-100 provides rugged industrial-strength, front panel IP65 protection, easy mounting, and I/O ports, making it an excellent choice for food production lines and any automated production scenario. NEXCOM's long-term service support backs all this.

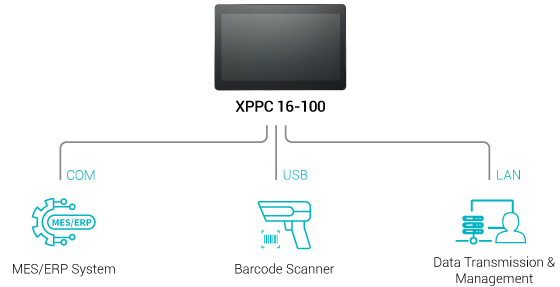

Application Diagram

Key Features for Application Needs

Key Features for Application Needs

- 15.6” TFT WXGA 16:9 panel

- 10 points P-Cap multi-touch with slim bezel design

- IP65 protection on the front

- Support: VESA/panel/openframe mount

- Intel® Celeron® processor J3455, Quad Core, 1.50 GHz

- 1 x DDR3L up to 8GB, M.2 M Key 2242 for storage device

- Support power input 19 VDC

- Related Links:

- NEXCOM Showcases Safe Humanoid Robot Controller, and unveils Slim AI-Ready Panel PC and Rugged Edge Solutions at Embedded World 2025

- The new XPPC10-10N97 and XPPC16-10N97 balances power and performance for logistics and self-service applications

- Browse Other News:

- Urban PET Recycling Reinvented Sustainable Solutions Powered by NDiS B561

- AIEdge-X®80 Leaps Ahead: Power Up TOPS Performance with NVIDIA® Jetson™ Super Mode

- All Case Study News