Industrial Wi-Fi Mesh Keeps AGVs Always Connected and On the Go

Overview

NEXCOM’s EZ Mesh Solution forms an industrial Wi-Fi network to keep automated guided vehicles (AGVs) always connected and humming with activities. As the demand for AGVs is thriving, AGV makers and system integrators (SIs) are looking for reliable wireless solutions to fulfill their promise of efficient, error-free, autonomous material handling to clients. That is why one of the leading AGV solution providers in China approached NEXCOM for its robust yet easy-to-manage EZ Mesh Solution.

Challenges

Uninterrupted data communication among AGVs and AGV control centers is the prerequisite for high transport efficiency and accuracy. However, in industrial facilities, such as warehouses and factories, quality network connections can be hard to come by not only because cabling for a wired network takes strenuous efforts, but also because the stability of a wireless network can be undermined by industrial machines and stockpiled inventory obstructing wireless signals. On top of that, administering a network can be a daunting undertaking for end clients.

NEXCOM's Solution

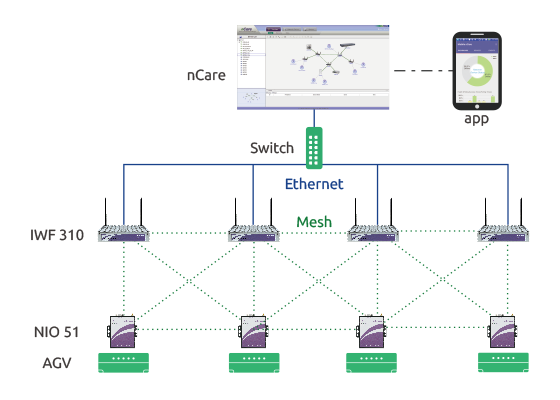

NEXCOM’s EZ Mesh Solution features IWF 310, NIO 51, and nCare, a remote network management tool, to setup and manage an industrial Wi-Fi network with multiple routes.

Expandable Resilient Network

The IWF 310 and NIO 51 serve as a mesh point on industrial premises and mobile mesh point in AGVs, respectively. Linking neighboring units, the IWF 310 and NIO 51 can elastically expand the Wi-Fi coverage to the whole operation area of AGVs, as AGVs navigate around, without being confined to locations of wired Ethernet outlets.

In addition, the interconnections among the IWF 310 and NIO 51 create numerous routes to ensure transport orders and inventory updates get through. When obstacles stand in the way of an established connection between an IWF 310 and NIO 51, transport orders can be sent to a designated AGV by taking a bypass route through another NIO 51 on AGV with the best possible signal strength to reduce data loss.

Manage with Ease

With dozens of IWF 310 deployed and NIO 51 moving around in warehouses and factories, managing an industrial Wi-Fi network would be an arduous task if not for nCare. After mesh points are in place, the remote network management tool can automatically scan and create a topology map, offering centralized configuration of mesh points and an overhead view of a network.

Network administers can be certain the industrial Wi-Fi network is reliable and all AGVs stay connected by remotely monitoring Wi-Fi signal quality, network links, and traffic loading; or opting to receive email, social media, or SMS alerts in case of network disruption. Also, nCare has a mobile app version to keep network administers alert on the go.

Industrial-Grade Sturdiness

The operating conditions can be harsh in industrial premises, not to mention AGVs where the NIO 51 is installed. To deliver industrial-grade sturdiness, NEXCOM’s EZ Mesh Solution features designs including a metal enclosure, an extended temperature range between -40 and 75 degrees Celsius, and high electromagnetic compatibility to guarantee system reliability against surrounding electronic noises and the lack of ventilation.

Solution Benefits

The deployment of such an industrial Wi-Fi network is easy with NEXCOM’s EZ Mesh Solution. The mesh technology reduces time and efforts associated with wiring, accelerating the setup and avoiding hassles for future revamp or expansion. Also attributed to the technology, the industrial Wi-Fi network is so resilient that it can self-form and self-heal network links and requires less human intervention. Although network monitoring is preferred occasionally, real-time network activities can be examined remotely, and events are logged to help network administers troubleshoot problems.

“We take connection quality to heart and find NEXCOM’s EZ Mesh Solution a trustworthy solution to our AGV applications. Having quality connections saves AGVs from connection retries, ensuring AGVs are always transporting goods as planned. More importantly, quality connections hold the key to accurate inventory updates and take an integral part in automated material handling,” said the AGV solution provider who has validated and recognized NEXCOM’s EZ Mesh Solution.

As a result, control centers can rely on the industrial Wi-Fi network to orchestrate a batch of AGVs—assigning transport orders and receiving inventory updates—automating inventory management and increasing operational efficiency.

- Related Links:

- NIFE 106: The Little Box That Does Big Things for Industrial Automation!

- Edge Computing and Automation Simplify Path to Green Manufacturing

- Browse Other News:

- NEXCOM to Unveil "Embodied AI Robots - Safe by Design" at NVIDIA GTC 2026

- Surge Immunity by Design: EMC Strategies for IEC 61850/IEEE 1613 Network Gateways

- All Case Study News