Accelerate and Elevate Manufacturing Operations with AI and Machine Vision

Digital Transformation Across Industry 4.0 Sector

Automation, leveraging artificial intelligence (AI) and other technologies bring new possibilities to industrial sector. In recent years, the pace of adoption has been rapid. Companies all around the world are leveraging automation to drive value. According to Deloitte's survey on AI adoption in manufacturing, 93% of companies believe AI will be a pivotal technology to drive growth and innovation in the sector. The main technologies that are driving digital transformation are machine learning, computer vision; chatbots and edge artificial intelligence (AI) drive adoption (Deloitte China, 2020).

AI Use Cases in Manufacturing Operations

Manufacturing companies are turning to AI to modernize the way they do business and increase efficiency. There are numerous possible AI use cases around all manufacturing processes. Some of these include the adoption of smart robots, AI, and predictive maintenance to improve production processes; automated quality inspection to ensure products of the highest quality levels; inventory management; and worker safety.

AI-enhanced predictive maintenance allows for better prediction and avoidance of machine failure by combining data from advanced Internet of Things (IoT) sensors and maintenance logs as well as external sources. Asset productivity increases of up to 20% are possible, and overall maintenance costs may be reduced by up to 10% (McKinsey & Company, 2017).

Quality control can benefit from AI, where the use of smart cameras and related AI-enabled software will help manufacturers achieve improved quality inspection at speeds, latency, and costs beyond the capabilities of human inspectors.

Inventory management with AI to predict consumer demand, manage supplier backorders and to optimize inventory stock levels. Using AI for inventory management can help making batter decisions as well as provide information for new investments.

Worker safety solutions that combine IoT and AI result in incorporating AI-trained analysts that detect and prevent workplace hazards and take real-time action to significantly improve safety. It can not only improve safety but also boost productivity. Gartner has predicted that, by 2021, AI augmentation will create $2.9 trillion of business value and recover 6.2 billion hours of worker productivity (Gartner, 2019).

Figure 1. AI applications in industrial automation.

NexAIoT Edge AI Solutions — Driving Performance, Integration, and Versatility

Manufacturers all over the world are under pressure to maintain a competitive advantage. Early interest in IoT and AI technologies is making way for more mature and permanent digital transformation programs. NexAIoT has worked with Intel® to bring AI enhancements to the existing iAT2000 Cloud SCADA system and Enterprise War Room to provide a bulletproof IoT solution. With these solutions, manufacturers can quickly deploy an integrated solution that automates the DevOps of digital factories and provides real-time production insights. NexAIoT takes “Industry 4.0 and AIoT” as its corporate vision and builds its R&D core competency on the innovative R&D concept of software-defined machines. Industrial 4.0 applications such as SoftPLC, HMI/SCADA, EtherCAT Motion & Robot Control, IoT Studio, and OPC Unified Architecture, One-Click to Cloud Dashboard, Diagnostics and ML Platform developed on a unified PC-based architecture, and accelerated by the embedded AI inference technology. NexAIoT is committed to assisting manufacturers in digital transformation and providing one-stop smart manufacturing services, including IIoT gateways, automation products, industrial computers, and Industry 4.0 customer system integration projects. NexAIoT is building OT/IT integration with ecosystem partners to co-create IIoT SaaS and alliance.

Simplify Development

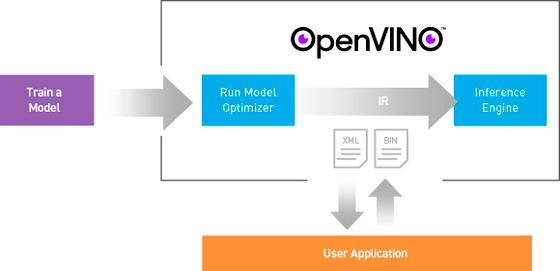

In cooperation with Intel®, NexAIoT is developing next-generation solutions for embedded applications supported by all modern operating systems, including high-level and real-time OSes, and Intel’s OpenVINO toolkit along with Media SDK.

The Intel® Distribution of OpenVINO toolkit enables users to optimize, tune, and run comprehensive AI inference using the included model optimizer and runtime and development tools. It is the all-in-one solution to develop and test computer vision applications, compare hardware performance, and choose the right platforms for various applications.

(Overview of the Intel® Distribution of OpenVINO™ Toolkit, 2021)

NISE 53 - Next Generation Fanless Embedded System for Industrial IoT

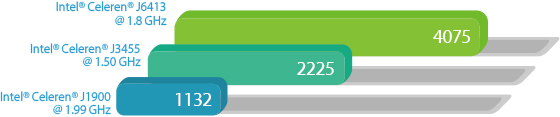

To support the next generation of IoT edge devices, NexAIoT has developed a brand new NISE 53 fanless industrial PC powered by Intel® processors enhanced for IoT — the 1.8 GHz Intel® Celeron® J6413, and Intel® Atom® x6211E processors. These processors achieve new levels of CPU and graphics performance with integrated IoT features, real-time performance, manageability, security, and functional safety.

Intel® UHD Graphics can support up to three independent HDMI displays. NISE 53 features in-band ECC DDR4 memory up to 16 GB, GbE Ethernet, Time-Sensitive Networking (TSN).

|

NISE 53 - HIGHLIGHTSIntel® Celeron® Processor J6413 Quad Core Fanless System

|

|---|

PassMark-Software-2021.jpg

Power-efficient Platform

Industrial IoT applications require a combination of a high-performance, low-power processor, robust real-time operation, wireless connectivity, and real-time hypervisor technologies. The NISE 53 is suitable for a wide range of low-power applications, including automation, smart robotics, PLC, and CNC controls for discrete manufacturing.

Superior Graphics

The NISE 53 takes a huge leap in graphics capabilities with Intel® UHD graphics 16EUs, and supports up to three simultaneous displays. The integrated GPU is ideal for 3D graphics and a wide range of GPGPU-driven applications as it supports major acceleration APIs such as DirectX 12, OpenGL 4.5, Vulkan 1.1, OpenCL 1.1, and metal.

Real-Time Connectivity

The NISE 53 is designed for industrial real-time applications and supports TSN — standards and capabilities based on standard Ethernet networks to support time-sensitive applications and supports time synchronization, timeliness for ultra-reliable low-latency communication, as well as traffic scheduling

Security at the Edge

NISE 53 Intel® Atom® and Intel® Celeron® based fanless embedded system features integrated security functions. Intel® AES New Instructions for wireless security, processor security, file encryption, and SSL/TLS. Intel® Secure Key is useful for generating high-quality keys for cryptographic protocols. In addition, Execute Disable Bit, Intel® OS Guard, and Intel® Boot Guard security features can reduce exposure to viruses and malicious-code attacks, and prevent harmful software.

Peripheral Connectivity and Expansion

NISE 53 offers expansion through PCIe Gen. 3, and supports efficient, scalable networks and storage configurations with an internal 1x M.2 slot (Key B) for 4G LTE, 1 x full-size mini-PCIe slot for Wi-Fi and Bluetooth, and front-accessible 1 x M.2 slot (Key B) for storage. I/O ports include 3 x HDMI, 3 x Gbe LAN, 2 x USB 3.0, 2 x USB 2.0, 2 x COM.

AI and Machine Vision Solutions

The NISE 53 supports Intel® Media SDK and OpenVINO™ toolkit to enable customers to build high-performance, intelligent vision solutions. Emulate human vision with the OpenVINO™ toolkit that provides a library of pre-made inference algorithms for character and Image recognition. Hardware-accelerated codecs can be used to offload media decode and encode workloads.

Extended Product Availability

The NISE 53 is designed for high reliability and long service life. Intel® processors offer ten years of continuous 24/7 operation (100% in sleep state S0), and currently, the standard availability of NexAIoT products is ten years.

Use Case: Production Data Analysis and Quality Inspection

For the long-term success of products and services, ensuring their quality through production quality assurance is of critical importance. Automated quality assurance systems typically require intense upfront investment and extensive testing and calibration. One example is the visual quality inspection systems often used to check the quality of products on production lines, e.g., printed circuit boards or car bodies.

Current automated approaches for visual inspection perform a pixel-wise comparison of the product for testing against an ideal reference image. Such a methodology is sensitive to even the slightest non-critical variations, so is only feasible if task-and environmentrelated preconditions are met. Ideally, perfect mounting of the product within the inspection tool is given, lighting conditions are the same across all inspections and types of defects are known in advance. Another crucial consideration is the operator’s trust in the results of the automated inspection process. A large number of false positives may reduce this trust, thereby eroding any benefits gained from automation.

Now, visual inspection methodologies based on computer vision and machine learning hold the promise of overcoming the challenges of comparison variations and false positives.

The recent advancements in AI-based quality assurance promise productivity increases of up to 50%. For AI-powered visual inspection, detection accuracy of defects increases while simultaneously flexibility is enhanced

Conclusion

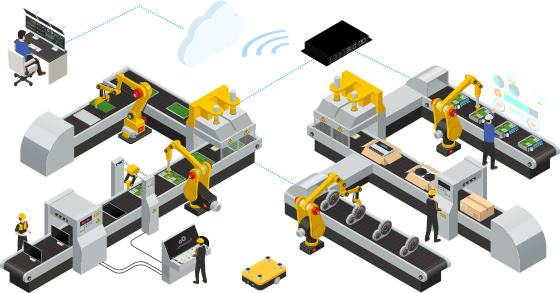

NexAIoT together with Intel® is developing a next-generation of industrial automation edge solutions for a wide range of applications and devices in factory automation, transportation, telecommunications and many other vertical markets.

Figure 2. Machine Learning in Production Data Analysis

References

McKinsey & Company. (2017, April). Smartening up with Artificial Intelligence (AI) - What’s in it for Germany and its Industrial Sector? Retrieved from McKinsey & Company, Inc.: https://www.mckinsey.com/

Deloitte China. (2020). AI Enablement on the Way to Smart Manufacturing. Deloitte. Retrieved from Deloitte Survey on AI Adoption in Manufacturing: https://www2.deloitte.com/cn/en/pages/consumer-industrial-products/articles/ai-manufacturing-application-survey.html

Gartner. (2019, August 5). Gartner Says AI Augmentation Will Create $2.9 Trillion of Business Value in 2021. Retrieved from Gartner: https://www.gartner.com/en/newsroom/press-releases/2019-08-05-gartner-says-ai-augmentation-will-create-2point9-trillion-of-business-value-in-2021

Overview of the Intel® Distribution of OpenVINO™ Toolkit. (2021, November). Retrieved from Intel: https://www.intel.com/content/www/us/en/developer/tools/devcloud/edge/learn/openvino.html

PassMark Software. (2021, November). Retrieved from CPU Benchmarks: https://www.cpubenchmark.net/compare/Intel-Celeron-J6412-vs-Intel-Celeron-J3455-vs-Intel-Celeron-J1900/4474vs2875vs2131

- Related Links:

- Physical AI Hits the Factory Floor: Predictive Optimization for Chemical Processes

- Step into the Future of Cybersecurity AI with NEXCOM at GITEX, Dubai

- Browse Other News:

- NEXCOM to Unveil "Embodied AI Robots - Safe by Design" at NVIDIA GTC 2026

- Surge Immunity by Design: EMC Strategies for IEC 61850/IEEE 1613 Network Gateways

- All White Papers News