NEXCOM Empowers Automobile Manufacturers in Data Collection from Production Line to Customer Insights

A prominent European car manufacturer was searching for an allencompassing solution to address its dual customer-facing and inhouse needs. The ideal solution would easily push content in their car showrooms to engage customers and evaluate their interactions while simultaneously collecting and displaying data from the assembly line. NEXCOM promptly answered the client’s call for help with a winning combination: the Neu-X300 edge computing system and XPPC10-100 touchscreen computer. With a wealth of I/O integrations for compiling and presenting critical information, these compact-sized and easily maintained computers were the best choice for the manufacturer’s external and internal uses.

Collect data from end customers

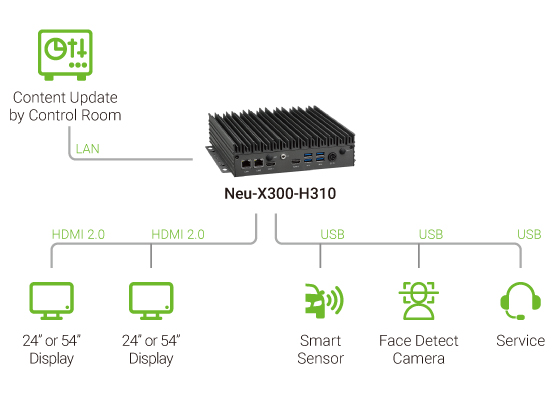

Purposely built for multiple applications, the Neu-X300 provides superior processing power, supports three separate 4K HDMI signals, and features a fanless design. The manufacturer’s particular choice of Intel’s Core i7 fueled its eye-catching video wall, interactive signage counter, and information kiosk. Various software integrations extended the embedded player’s capabilities beyond mass-audience signage to customized displays, utilizing audience measurement to detect customers’ reactions and gauge interest, and RFID sensors to identify objects that customers grasped and consequently show responsive ads. The fanless design also meant that the Neu-X300 was space-efficient, allowing the client to deliver powerful images and advertisements without the clutter of industrial-size computers.

Collect data from the production line

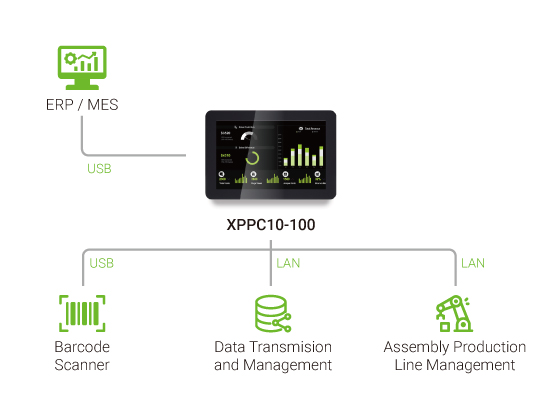

Not only did NEXCOM meet the automobile manufacturer’s marketing and sales needs but also increased production accuracy and traceability through the XPPC10-100. The panel PC’s system architecture enabled real-time data collection by including various I/O connections requisite for industrial environments such as the client’s assembly lines. For example, it linked to ERP/MES systems and barcode scanners via USB, whereas its LAN ports provided data transmission and production line management. What’s more, the XPPC10-100’s IP65-rated front panel is protected against dust or water projections, ensuring that the client would avoid replacement expenses due to accidental damage.

Put the total solution at your fingertips

NEXCOM is the leader in providing IoT devices for customers’ digital transformation needs. When integrated with appropriate software, NEXCOM’s comprehensive combinations, such as the Neu-X300 and XPPC10-100, are the ultimate fit for a multitude of applications, saving customers time and money.

Application Architecture

- Related Links:

- NEXCOM Showcases Safe Humanoid Robot Controller, and unveils Slim AI-Ready Panel PC and Rugged Edge Solutions at Embedded World 2025

- The new XPPC10-10N97 and XPPC16-10N97 balances power and performance for logistics and self-service applications

- Browse Other News:

- NEXCOM at Embedded World 2026: Unleashing the Ingenuity of Software-Defined Edge Computing

- Smarter Healthcare Self-Service Starts with Neu-XE102 & XE104 Edge Computing

- All Case Study News