Industrial Wi-Fi Infrastructure in High-Temperature Steel & Iron Factory

Background

Background

In this medium-scale steel and iron factory, high temperature and dust conditions are common situations.

A Taiwan-based customer had deployed an ERP and shop floor control system as centralized management to manage work flow. It worked well until the customer needed a mobile operation that can deliver a seamless anywhere, anytime coverage. The existing commercial grade Wi-Fi APs (Access Point) were not reliable enough in the high temperature, dusty shop floor and outdoor environments. Moreover, without a central Wi-Fi management mechanism, the MIS staffs had difficulties in managing APs deployed widely throughout the factory.

Challenge

Since the customer expects workers can freely roam throughout shop floors with rugged hand-held terminals connected to the ERP system and upload and download information remotely in real time, the MIS team faces some challenges:

Since the customer expects workers can freely roam throughout shop floors with rugged hand-held terminals connected to the ERP system and upload and download information remotely in real time, the MIS team faces some challenges:

- How to keep the Wi-Fi communication running non-stop in critical shop floors?

The previous commercial grade AP often failed to work, especially the ones near the operating areas and during hot summer seasons. The APs were installed inside shield boxes that were placed outdoors with an ambient temperature higher than 70 degrees Celsius. - How to easily & quickly expand the Wi-Fi coverage?

Some outdoor areas and new pre-planned work sites like material incoming/receiving areas are difficult and costly to install wired networks. - How to efficiently manage factory-wide Wi-Fi APs?

The MIS staffs found it is difficult to access or manage APs deployed in high floors and dangerous areas. The upgrade and maintenance of these APs were troublesome to the staffs located in the central MIS office as the shop floors operated 24 hours daily.

Customer Needs

To resolve the unreliable AP operation and unexpected shutdowns during summer, the customer sought for a reliable and manageable industrial-grade Wi-Fi infrastructure. Flexible and integrated AP deployment without extra licensing is also another concern. Hence, the requirements were as followed:

To resolve the unreliable AP operation and unexpected shutdowns during summer, the customer sought for a reliable and manageable industrial-grade Wi-Fi infrastructure. Flexible and integrated AP deployment without extra licensing is also another concern. Hence, the requirements were as followed:

- Industrial-grade AP solution

- Fully and reliable Wi-Fi coverage

- Flexible expansion

- Centralized management tools

Why NEXCOM Solution

NEXCOM's central managed WLAN control solution perfectly fulfills the customer needs and allows headroom for future expansions such as point-to-point communication and wireless video surveillance.

- IWF 8405: Central management Wi-Fi solution

- AAA certified WLAN controller

The IWF 8405 WLAN controller utilizes proprietary protocol to manage IWF series of APs and simplify the IT manager's administration tasks of monitoring, configuring and maintaining the APs remotely, even across other factories.

- No license fee for future Wi-Fi APs management & expansion

NEXCOM IWF 8405 manages up to 150 APs without extra license fees. - IWF 3320X: Industrial-grade AP

- Protection against high temperature and dust

IWF 3320X can operate in wide temperature ranges of -30 to 80 degrees Celsius. The unique conformal coating on the motherboard can resist dust, rain and chemical erosion.

- Dual RF supports reliable, flexible and redundant Wi-Fi deployment

NEXCOM's APs are armed with two radio cards supporting 2.4GHz/5GHz for flexible Wi-Fi deployment.

- Point-to-point (P2P) and point-to-multi-point (P2MP) wireless bridging

NEXCOM IWF series of APs provides up to 4 connections of Wireless Distribution System (WDS) to easily bridge nearby APs.

Application Scenario

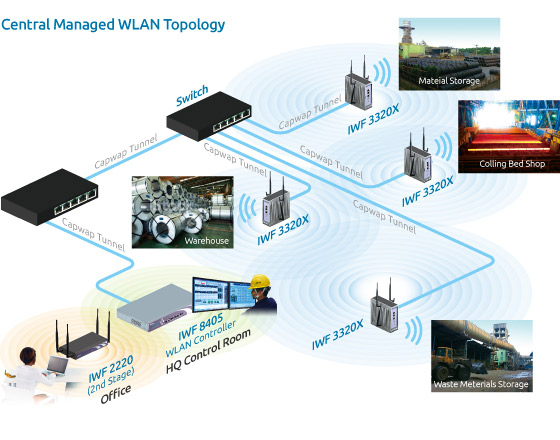

Stage 1: PAN-based factory with mobility operation & central management

Stage 1: PAN-based factory with mobility operation & central management

An IWF 8405 WLAN controller was used to monitor the IWF 3320X APs located within the factory. Each IWF 3320X established a CAPWAP tunnel between the access controller to transmit its AP status, and data tunnels between mobile clients to exchange Wi-Fi traffic.

Stage 2: Wi-Fi coverage expansion for video surveillance and automation data acquisition of new plants

More outdoor APs, IWF 5320, and light-duty indoor APs, IWF 2220, will be deployed in the field and office.

Conclusion

After 6 months of deployment, NEXCOM's central managed industrial Wi-Fi solution has delivered zero downtime. With the great success of NEXCOM's IWF solution, the customer plans to install IWF 5320 for outdoor IP surveillance and IWF 2220 for the office in the upcoming second stage of the project. Utilizing NEXCOM's manageable WLAN controller and industrial-grade AP solution, the customer can easily manage their Wi-Fi infrastructure remotely from the office without having to worry about the wireless APs running in harsh environment.

- Related Links:

- Urban PET Recycling Reinvented Sustainable Solutions Powered by NDiS B561

- Enhancing Logistics Efficiency with NDiS B561 Integrated Dimensioning Solution

- Browse Other News:

- NEXCOM to Unveil "Embodied AI Robots - Safe by Design" at NVIDIA GTC 2026

- Surge Immunity by Design: EMC Strategies for IEC 61850/IEEE 1613 Network Gateways

- All Case Study News