Utility and Environmental Safety Monitoring

NEXCOM IoT Solutions facilitate utility and environmental safety monitoring for manufacturers. Small or large, plants employ a wide variety of systems to supply and monitor the use of water, air, gas, electricity, and steam required of production. In the meanwhile, all solid, liquid, and gaseous waste that comes along with production must be captured and treated to regulatory standards. With the need to ensure efficient resource consumption, workplace safety, environmentally friendly operations, and regulatory compliance, manufacturers rely heavily on manual collection of field data. However, the practice is labor-intensive, the data is not real-time, and an abnormality that requires immediate attention is out of the question.

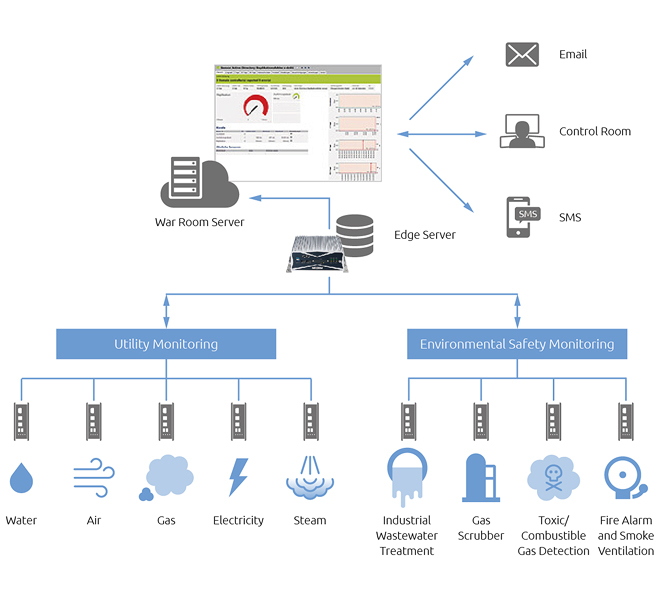

In this regard, NEXCOM offers one-stop service from planning to implementation to make remote, real-time monitoring possible. Based on Internet of Things (IoT) technologies, NEXCOM can deploy an end-to-end installation to automate data acquisition, integrate private clouds, present real-time data and historical trends, and alarm operators to an abnormal event.

Application Diagram

Application Scenario

Production Quality Control: The cleanroom environments are instrumental to production quality of printed circuit boards (PCBs). PCB manufacturers can monitor and control the level of contamination, humidity, and temperature to stabilize PCB yields.

Implement Corrective Actions: The cloud integration supports remote monitoring and third-party service integration. Manufacturers can opt in for email or SMS notifications which warn the responsible personnel about, for example a data set falling out of a specified range, enabling corrective actions to be implemented in time.

- Related Products

- NISE 3700E