Raw Material Management

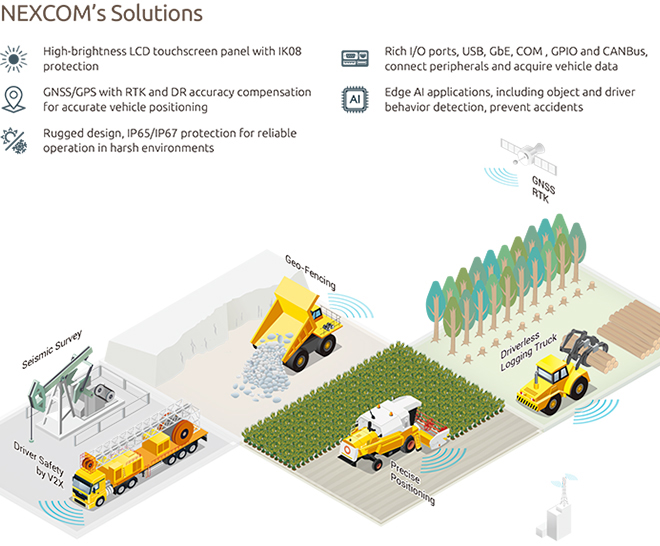

For Raw material management, NEXCOM in-vehicle computers are superior in handling the process of monitoring, tracking, and optimizing the usage of raw materials or resources required for the vehicle's operation and maintenance. Due to the rugged design, NEXCOM in-vehicle computers are suitable for various types of vehicles, including tractors, trucks, construction equipment, and industrial machinery.

Incorporating raw material management into NEXCOM in-vehicle computers can lead to more efficient operations, cost savings, and improved safety. The vehicle's operator or fleet manager can access real-time information about raw material levels through the vehicle's dashboard. This helps in making informed decisions and taking timely actions.

Mining truck is a piece of powerful equipment and also the dangerous vehicle in the Mine construction site. NEXCOM in-vehicle computers with ADAS technologies, when implemented in mining trucks, contribute to improved safety for both the operators and others working in the vicinity. The ADAS technologies can include collision avoidance technologies, AI accelerator, object detection sensors, and PoE/MIPI cameras to assist the driver in avoiding obstacles, other vehicles, or personnel in the mining area.

NEXCOM ensures that its in-vehicle computers are designed with robustness to withstand the challenging conditions of a mining environment.

PDF Download |

|---|

- Related Products

- VTC 1031/1031-C2 VTC 7252-7C4IP VMC 220