The Critical Characters of an Industrial Panel PC

Powerful Processor

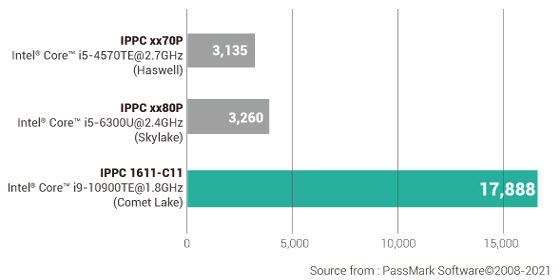

When the panel PC is used as an independent control unit, powerful computing power becomes extremely significant. adopts the latest 10th Generation Intel® Comet Lake CPU. The socket type design allows users to install CPUs with different computing capabilities according to computing needs, including Celeron®, Pentium®, Core™ i3/i5/i7/i9. The 10th Generation Intel® Core™-i processors has up to 31% enhanced integer multi-tasking as well as, up to 11% improved integer single task compute intensive application performance when compared to the 9th Generation Intel® Core™-i processors. Taking NexAIoT’s IPPC 1611 for example, its overall efficiency is 5~6 times greater than similar products on the market today. Due to industrial systems usually having to operate 24/7, it requires high levels of reliability and uptime, making operations smarter, more connected, and more autonomous.

Upgradability: Modularize Panel Kit and Box PC

Industrial panel PC design does not only consider scalability, but also product diversity and system upgradeability. The IPPC 1611-C11 divides into two main modules: panel kit and box PC. With the combination of the two modules, different panel PCs can be combined according to the needs of use.

- Panel kit: It is mainly composed of mechanical parts, touch, and panel. Modules with different panel sizes or different touch functions can be reformed. IPPC 1611-C11 provides 21.5 and 23.8-inch panels in addition to the original 15.6 inches.

- Box PC: In addition to providing easily upgradeable CPU, memory, and SSD, IPPC 1611-C11 also provides various expansion slots. Furthermore, it can be replaced with different systems according to the original design to meet the needs of different users.

Extensibility and IIOT

In the current user scenario, the industrial panel PC is no longer an independent unit, but needs to be connected to the network, even as a part of edge computing. IPPC 1611-C11 offers a complete expansion interface, including 5G/LTE wireless connection, Wi-Fi, storage expansion, and PCIe interface cards for special needs. For 5G wireless connection, it provides the most commonly used M.2 3042/3052 Key B socket and a mini-PCIe socket for Wi-Fi usage. If the latter socket is not used, installing mSATA can be an option. Moreover, when additional storage space is required, IPPC 1611-C11 has a M.2 2242 Key B socket. As for extra PCIe interface card requirements, such as the industrial motion control card, it can then be installed on the PCIe x4 socket of the device.

|

|

|

|||||||||||||||||||||||||||||||||||||||

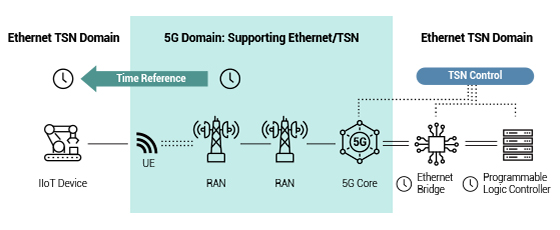

As Ericsson mentioned, Time-Sensitive Network (TSN) and 5G are essential for the Industrial Internet of Things (IIOT). Predetermined services provided by TSN over IEEE standard 802.3 Ethernet wired networks, promise low/bounded latency, low packet delay variation, and low packet loss in its packet transport. Its features can be enabled for particular data streams in a network, which also handles best effort traffic types. Connecting industrial devices wirelessly to a TSN network is where 5G comes in. In contrast with 4G, 5G offers better reliability, latency transmission, and system architecture. In overcoming the limitations of cable installations, 5G can extend TSN networks.

|

|

Figure: Overview of the TSN integration |

Although, the existing processors has yet to provide TSN function, with the TSN network card installation, IPPC 1611-C11 will have TSN and 5G networking to achieve IIOT requirement. This high extensibility designed in IPPC 1611-C11 focuses on both current and forthcoming applications.

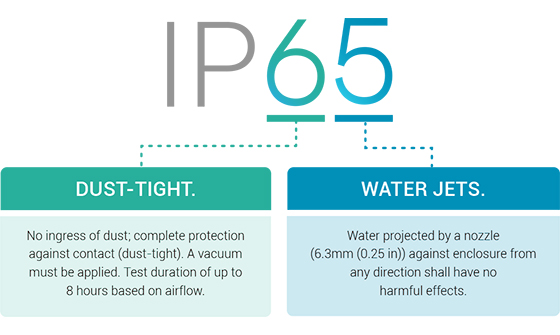

Protection from Water and Dust: IP65

IP rating is formulated by the International Electrotechnical Commission (IEC); providing a guideline regarding the degree of protection required in mechanical casings and electrical enclosures against intrusion, dust, and accidental contact. As an industrial panel PC, object intrusion prevention is very significant for it to be fully functional in various harsh environments, such as factories, stations, gas stations, or agricultural machinery. NexAIoT’s IPPC 1611-C11 fulfills these crucial specifications by fulfilling the IP65 (waterproof and dustproof) front panel standards. In the case of panel mount installation, it completely prevents the intrusion of foreign objects/dust, and low-pressure water jets in various angles from entering the device.

|

Certification of Industrial Environments

An industrial panel PC is mainly operated in indoor and outdoor industrial settings. For such harsh environment, the IEC 61000-6-2 and IEC 61000-6-4 certifications are definitely indispensable.

- IEC 61000-6-2: This standard applies to electrical and electronic equipment, either to be directly connected to DC distribution network or battery operated and is intended to be operated in industrial locations, both indoors and outdoors. The 61000-6-2 test standard is to define test requirements for radiated and conducted immunity, including electrostatic discharges of electrical and electronic devices for industrial locations. The levels do not cover low probability extreme cases, however, the panel PC can still operate normally under the above-mentioned environmental disturbance.

- IEC 61000-6-4: This standard defines the emission test requirements for apparatus defined in the scope of continuous and transient, conducted and radiated disturbances. The emission requirements have been selected to ensure that disturbances generated by apparatus operating normally in industrial locations do not exceed a level that could prevent other apparatus from operating as intended. Fault conditions of apparatus are not taken into account, meaning the panel PC does not affect other devices in the above state.

Besides the IEC 61000-6-2 and IEC 61000-6-4 certifications, IPPC 1611-C11 operates its system in a very stable manner. For instance, the system will sometimes shut down or get damaged in industrial environments with unstable power supply. However, the IPPC 1611-C11 designed to offer 24V wide voltage power input, with variable range of up to 20%, can operate normally in such situation. This power input design can effectively prevent damage to the system from high voltage, or operation error/system shutdown due to low voltage. As for the huge signal interference of COM port connection over long distances, the IPPC1611-C11 adopts isolation countermeasure and adds ESD protection components to avoid signal interference and surge impact.

Various Mounting Support

The usage of industrial panel PC can usually be classified into three installation methods including:

- Wall mount: By installing the panel PC on the wall, it can effectively save space, preventing the panel PC from being affected by earthquakes or collisions. IPPC 1611-C11 provides VESA 100x100 holes for wall mount kit installation.

- VESA mount: The VESA mounting interface defines the distance between the 4 screw holes on the bracket or behind the screen. Taking the most common FDMI MIS-D as an example, VESA 100x100 represents the horizontal spacing and vertical spacing of screw holes. The spacing is 100mm, and the VESA 75x75 is 75mm apart. When installing, just align the screen with the same holes spacing with the bracket holes, and then lock the screws to fix the screen to the bracket. The VESA bracket is usually a desktop or wall cantilever and has a lock plate that conforms to the VESA Association standard. After locking the panel PC, it is fixed on the desktop or wall. VESA mounting not only save space, prevent damage from earthquakes and collisions, it allows panel PC to easily adjust various viewing angles and heights.

- Panel mount: It is a common installation method for industrial outdoor environments. By being embedded in the box or wall, only the waterproof and dustproof panel portion will be exposed, overcoming the relatively harsh environment. The IPPC 1611-C11 provides a dedicated panel mount kit, which can be mounted on a 2mm thickness plate, has IP65 certification, and fulfills the vibration/shock test standards.

The Sensible Decision

The IPPC 1611-C11, NEXAIoT’s powerful panel PC is designed for industrial applications and is equipped with the latest technologies. It offers users, ultraefficient performance as compared with its competitors. Its characteristics include recyclable and impact resistant metal housing for system cooling. Moreover, IPPC 1611-C11 adapts a fanless design, decreasing malfunction possibilities. In terms of standards, this system has fulfilled IP65, IEC 6100-6-2 and IEC 61000-6-4, which are all significant for harsh environment operations. With a rich expansion interface, flexible system upgradability and several mounting options, it is an ideal solution for all current vertical market trends such as, IIoT and AIOT. Many solution providers and system integrators are currently facing numerous tasks and are in need of a platform solution in accordance to their project-specific requirements. In order to fulfill these requirements and future indefinite requirements, NEXAIoT’s IPPC 1611-C11 is the key, offering economical, sturdy and reliable industrial panel PC for 24/7 harsh industrial IoT operations.

Reference

[1] Ali, S. M. Industrial connectivity in the ERA OF TSN, APL and 5G. OMDIA Tech Informa: 01.01.2020.

https://omdia.tech.informa.com/OM006472/Industrial-connectivity-in-the-era-of-TSN-APL-and-5G

[2] Furbush, J. What is OPC UA and why is it essential for automation. Cognex: 10.22.2019.

https://www.cognex.com/blogs/machine-vision/why-opc-ua-is-essential-for-factory-automation

[3] Ivezic, M. 5G in Manufacturing - 5G and Time Sensitive Networking (TSN) for Industrial Automation. 5G Security: 04.10.2020.

https://5g.security/5g-technology/5g-tsn-industrial-automation/

[4] Lin, J. How TSN is Revolutionizing Industrial Automation. Industrial Ethernet Book: 03.30.2021.

https://iebmedia.com/technology/tsn/how-time-sensitive-networkingis-revolutionizing-industrial-automation/

[5] Patel, D., Ashraf, M. I., & Palaios, A. (2018, December 18). 5G Meets Time Sensitive Networking. Ericsson Blog: 12.18.2018.

https://www.ericsson.com/en/blog/2018/12/5g-meets-time-sensitive-networking

[6] Zhang, J. 5 Things You Should Know That Time-sensitive Networking Can Accomplish For the IIOT and Industry 4.0. MOXA: 03.09.2021.

https://www.moxa.com/en/articles/5-things-you-should-know-tsn-iiot-applications

- Related Links:

- NEXAIoT at 2021 Automation Taipei - Driving Sustainable Development

- NexcomEMS Provides One-stop Services for Its Partners

- Browse Other News:

- NEXCOM to Unveil "Embodied AI Robots - Safe by Design" at NVIDIA GTC 2026

- Surge Immunity by Design: EMC Strategies for IEC 61850/IEEE 1613 Network Gateways

- All White Papers News