Physical AI Hits the Factory Floor: Predictive Optimization for Chemical Processes

Background

The chemical manufacturing sector is a cornerstone of the global economy. According to the International Council of Chemical Associations (ICCA), it contributes $5.7 trillion annually — approximately 7% of global GDP — and supports over 120 million jobs. As the fifth-largest manufacturing sector, it generates $1.1 trillion in direct output each year.

In Taiwan, the chemical industry holds similarly critical importance, ranking third in manufacturing output in 2022, behind only electronics and metal machinery. The sector — from petroleum refining to synthetic fibers — relies on continuous production lines where long, uninterrupted equipment runs are essential and process stability is crucial. Even minor deviations in key parameters can compromise product quality and pose safety risks. While historically reliable, traditional quality monitoring methods such as routine inspections, SPC charts, and operator experience are becoming less effective as product complexity increases and process variables multiply.

NEXCOM and Profet AI have surveyed the market and consulted with numerous companies across the pan-chemical industry to identify the lingering pain points on production lines. Discover how their joint solution tackles the challenge by bringing AI into physical world.

Where the Gaps Were

When deviations in product quality occurred, such as shifts in purity or physical properties, teams often spent days searching for the root cause. This typically involved sifting through equipment logs, cross-checking historical parameters, and running trial batches to isolate the issue. But in an environment where time-to-correction matters, this kind of approach fell short:

- Highly interdependent parameters made it difficult to pinpoint the root cause of quality issues

- Trial-and-error approaches prolonged process adjustment cycles

- Heavy reliance on tacit knowledge slowed response and hindered reproducibility

- Lack of reliable edge processing platform that provides both AI computing capabilities and legacy device compatibility

Physical AI: From Hardware, Software, to Physical World

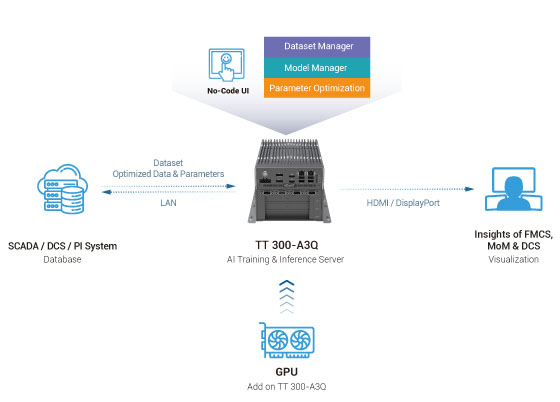

NEXCOM's industrial PC, combined with Profet AI’s AutoML platform, empowers process engineers to locate the root causes of quality fluctuations by AI training and inference.

NEXCOM TT 300-A3Q is a compact and high-performance system designed for factory automation and AI model training. Its PCIe x16 expansion slot can accommodate high-end GPU, providing the essential computing power for AI training and other advanced applications. The 4 x COM ports and 2 x GbE LAN ports offer ultimate connectivity to field devices, and the 2 x HDMI® & 2 x DP ports are perfect for quad 4K HDR displays, providing the elastic configurations of display matrix for intelligent operation center.

Via NEXCOM TT 300-A3Q, the AutoML platform receives process data from the production line, including temperature, pressure, liquid level, and flow rate. With the platform's no-code interface, engineers easily build predictive models on historical datasets, linking process variables to quality outcome. Key contributing factors are presented through inference by the models, allowing engineers to focus on the parameters that mattered most. Engineers can also explore how different operating conditions influence quality predictions using the models, which provides early visibility into potential outcomes, proactively guiding parameter adjustments even before the results are available.

Reframing the Approach: What You'll Discover

- A clearer picture of which variables are driving product variation

- Faster diagnosis of abnormal conditions: Trial-and-error cycles reduced by 57%~61%

- Precise guidance for parameter adjustments: Validation time drops from 3-5 days to less than 1 day

- Product stability improves by 28%

Importantly, none of these gains requires reorganizing teams or building an enormous analytics team. The breakthrough comes from equipping the people closest to the work with the right tools.

More Than a Fix, a Repeatable Process

What once relied solely on experience becomes something visual, traceable, and reusable. Each model built is automatically documented — its structure, input, output, key variables, and how predictions perform is all well recorded. This transformation turns individual process knowledge into shared organizational intelligence.

It is not only a one-time success; it marked the beginning of a repeatable improvement system, where lessons learned on the field can be reproduced, scaled, and shared across teams and production lines anywhere.

About NEXCOM: https://www.nexcom.com/index.html

- Related Links:

- Step into the Future of Cybersecurity AI with NEXCOM at GITEX, Dubai

- NEXCOM to Showcase Cutting-Edge Software-Defined Edge Computing Solutions at Embedded World North America 2024

- Browse Other News:

- NEXCOM to Unveil "Embodied AI Robots - Safe by Design" at NVIDIA GTC 2026

- Surge Immunity by Design: EMC Strategies for IEC 61850/IEEE 1613 Network Gateways

- All Use Case News