Smart Harbor & Port Automation Solutions

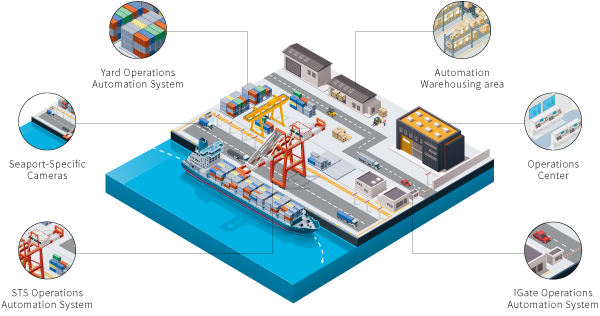

How Does a Smart Seaport Operate?

Seaport-Specific Cameras × High-Quality Imaging

This system utilizes SeesAll™ industrial-grade cameras and front-end hardware specifically designed for harsh seaport environments. It overcomes conditions such as corrosion, salt spray, dust, strong winds/operational vibrations, heavy rain, high humidity, and extreme temperature fluctuations, ensuring accurate 24/7 image capture and recognition rates. This guarantees the long-term reliable operation of automated systems while reducing cleaning frequency, the risks associated with manual high-altitude maintenance, and overall costs.

AI Smart Image Processing × Precise Operations

The system automatically captures images from all on-site checkers. These are processed and analyzed in real-time via a front-end AI image processing engine, which avoids adding load to existing networks and servers, thereby maintaining stable system operation. By reducing manual data entry and inspection, it lowers the risk of human error and enhances processing speed and data accuracy.

Key Benefits

- Centralized Exception Management × Enhanced Occupational Safety

All information is integrated into the control center in real-time for centralized handling of all on-site situations. In the event of an anomaly, dispatchers can react and make decisions immediately through the exception management system. This reduces the need for front-line personnel to perform inspections in high-risk environments (such as heavy machinery operating areas), significantly improving overall occupational safety. - Reduced Container Truck Turnaround Time

Fully automated identification and task handovers increase port throughput. By shortening the dwell time of container trucks within the terminal and improving gate-in/gate-out efficiency, the system prevents unnecessary waiting and traffic congestion. - Container Damage Documentation × Traceability

During every import and export process, the system automatically archives container condition images and relevant records. This serves as evidentiary data for subsequent insurance claims, liability clarification, and dispute resolution. - Seamless Integration × Field-Proven Validation

Through standardized software development kits (SDK / API), DivioTec automated systems can be easily integrated with various TOS, YMS, WMS, and ERP systems. It supports existing IT/OT architectures in port and logistics environments (such as PLC electronic control systems from SIEMENS, ABB, TEMIC, etc.). The system has been successfully deployed hundreds of times in major terminals and logistics hubs worldwide, with extensive applications in port authorities and government projects. With over 25,000 container trucks passing through DivioTec systems daily, we possess mature and scalable real-world operational experience.

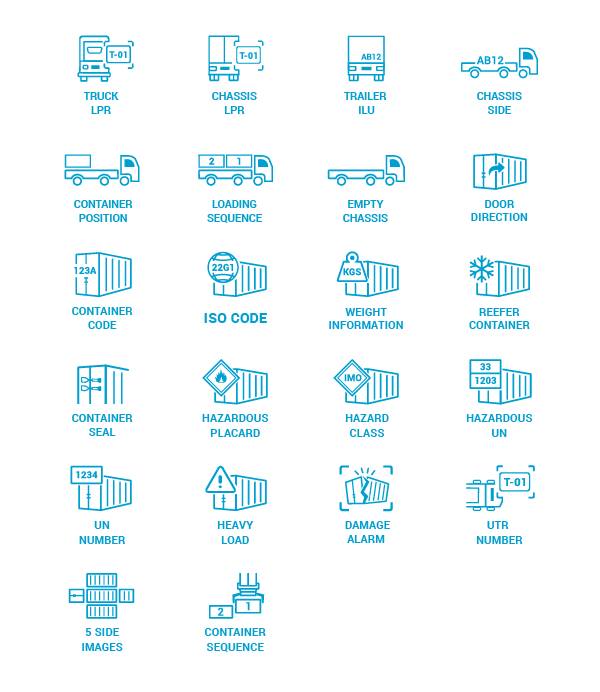

What Can the System Identify?

Gate Operations Automation System

STS Operations Automation System

Yard Operations Automation System

Operations Center | Truck Tracking and Management System