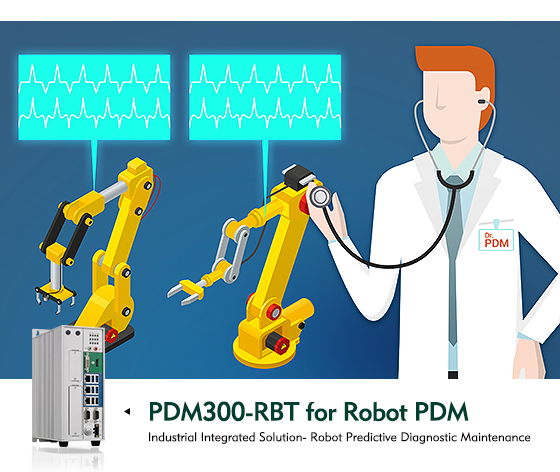

NexAIoT’s PDM300-RBT Robot Predictive Diagnostic Maintenance Package: The Industry Game Changer

With the rise of Industry 4.0, robots have become increasingly prevalent and indispensable in manufacturing. But if anything were to happen to them, it would create serious operational issues and catastrophic impact on business. To resolve these issues, NexAIoT is proud to launch the PDM300-RBT, the world’s first robot PDM solution. Using machine learning and quick model building, the cost-effective and easy to configure PDM300-RBT is a complete hardware and software package that lets you monitor and tune robots so you always stay ahead and keep downtime to a bare minimum.

Universal Solution for Training and Optimizing Industrial Robotics

The PDM300-RBT was designed based on input from robotics end users and vendors and built for real world applications that require fast response and quick AI-based robot predictive diagnostics. It works on various robotic types, such as delta, SCARA, and other articulated robots. As a total solution, it includes everything you need: gateway, sensors, and, of course, the NexAIoT software suite for monitoring, adjusting, and optimizing robot performance. Thanks to the intuitive GUI and clear application usage of our software suite, you no longer require a diagnostic engineer dedicated to monitoring robot optimization, resulting in considerable savings.

Fast Deployment, Rapid Action

Unlike traditional and cumbersome solutions that may need weeks or months to install and become effective, the compact PDM300-RBT sets up in mere minutes and gets working immediately. The adaptive AI we developed to handle precision robot predictive diagnostics needs as little as three minutes to begin formulating patterns for your specific robot chain, working with standalone, magnetic sensors that attach to any surface near robots and do not require permanent drill-in fitment. The PDM300-RBT offers a neat but powerful add-on solution that elegantly slips in and out of any industrial setting on demand.

Predictive Diagnostics Improve Operation and Eliminate Downtime

Sensitive to even the most minor changes in behaviors, including patterns, energy, or activity, PDM300-RBT sensor arrays detect vibrations to gauge robot output and overall machine health. Alerts and alarms inform you of any sudden decline in robot performance or other suspicious events, while our AI learns your environment to suggest an optimal workflow that you then use to fine tune robot units and achieve better operation.

Should any robot show even the slightest deviation from desired parameters, the system sends out notifications so maintenance can pre-empt any major failure. Consequently, you avoid one of the most common sources of downtime: undetected, preventable robot failure.

High Speed Detection Perfect for Burst Operation Robots

Contrary to industries based on machines that operate in a very consistent, predictable manner, quick-action robots perform intricate and sudden moves. They also constantly change motions depending on the products worked on and thus need a suitably fast and adaptable system to help monitor them. With lag-free sensors and diagnostics, the PDM300-RBT does more than keep up with robots, it stays ahead of them at all times. Advanced robot predictive diagnostics algorithms further help users trace a complete workflow and employ diagnostic data to pinpoint the exact time any change took place, creating a clear context for robot conditions and performance.

Superb Cost Performance Ratio for Any Robotics User

Working with numerous end users, NexAIoT learned that the sweet spot for a diagnostic system hovers around 10% of the cost of each robot. Thus, we have priced the PDM300-RBT aggressively to offer an excellent value proposition with all the features of solutions that are multiple times costlier and yet slower.

The Companion All Robots Love

For any users and vendors that want to ensure optimal performance and care about the health of their robots, the NexAIoT PDM300-RBT delivers in spades thanks to its advanced robot predictive diagnostics maintenance capabilities. In addition to superb management and dynamic predictive AI, the package includes cloud connectivity to IoT platforms and its low profile, compact size, and energy efficiency makes predictive diagnostics so good, you won’t need a crystal ball.

Main Features

- AI-based automatic diagnosis

- Automatic diagnosis 24/7

- One-to-one paired installation

- Easy installation and setup

- IoT connectivity

- Application targets: DELTA, SCARA, articulated robot

Ordering Information

PDM300-RBT_34D_D1SW (P/N: 10PDM300RBTXR)

Robot Predictive Diagnostic Maintenance

- Related Links:

- Boost Bus Safety and Protect Valuable Assets with the ATC 3561

- Rugged, All-Around Performance for Transportation: Meet the VTC 6232/nROK 6232

- Browse Other News:

- Achieve Faster AI Insights with NEXCOM FTA 5190 and Xeon® 6 SoC

- NEXCOM Showcases Safe Humanoid Robot Controller, and unveils Slim AI-Ready Panel PC and Rugged Edge Solutions at Embedded World 2025

- All Products News