NEXCOM Stays Ahead with Rapid Innovation of Industry 4.0 at 2017 Hannover Messe

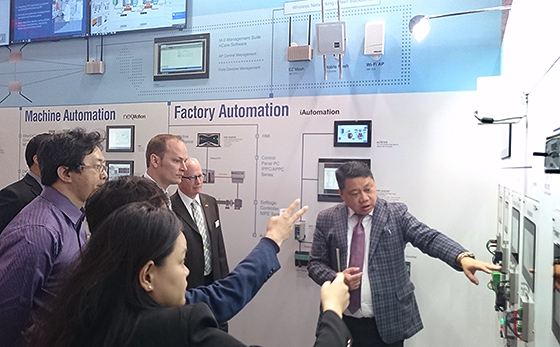

As automation players from worldwide gathered at the Hannover Messe presenting the rapid innovation of Industry 4.0, the 4th industrial revolution is no longer a future vision but reality. The crystal clear presence of NEXCOM’s Industry 4.0 Solution Map helped visitors identify which solutions met their demands to build a digital factory with ease. The most frequently-asked solutions at the event, Cloud SCADA and Industrial Network, which also happen to be hitting the trends nowadays, show that NEXCOM is not only on the right track in this revolution, but also staying ahead with rapid innovation.

NEXCOM's complete Industry 4.0 Solution covered the three layers to establish connectivity from edge to cloud to streamline manufacturing processes, optimize production efficiency, exchange raw data over the network and turn them into valuable information. Based on the map’s concept, NEXCOM demonstrated a whiskey factory scenario with its Cloud SCADA and Control Solution. It showcased how the NIFE 105 master controllers running different fieldbus protocols to control and interlock other operation processes as an error occurred in one of the processes. At the same time, the Microsoft Azure Cloud-based SCADA systems worked to optimize process efficiency, improve operation and reduce cost. The Cloud SCADA and Control solution pushed field data from the controller to cloud to optimize equipment operation and helped enterprises make insightful decisions and increase competitiveness.

For the Industrial Network Solution, the IIoT gateway CPS series, which are designed for vertical application purposes, was the star at the show. In order to unify the communication in a digital factory from edge to cloud, the CPS series gateways were equipped with a wide selection of different fieldbus protocol and cloud protocol support. On the site, a predictive maintenance scenario, running on CPS series gateway and Microsoft Azure, showcased how it could maintain a log to track the health of industrial machines, alert client service engineers to diagnose machine health status, look for signs of performance degradation, and schedule a maintenance visit, if necessary, before a machine malfunction.

Last but not least, the field data security will be in tremendous demand when all things are connected in a digital factory. NEXCOM’s industry firewall IFA series features advanced firewall architecture and stateful packet inspection to detect and prevent intrusions at the end point. The IFA series can arm industrial appliances with endpoint firewall protection and secure VPN connection, enabling users to remotely manage industrial appliances with peace of mind.

For more information, please contact NEXCOM's sales representatives.

- Related Links:

- NIFE 106: The Little Box That Does Big Things for Industrial Automation!

- Edge Computing and Automation Simplify Path to Green Manufacturing

- Browse Other News:

- Achieve Faster AI Insights with NEXCOM FTA 5190 and Xeon® 6 SoC

- NEXCOM Showcases Safe Humanoid Robot Controller, and unveils Slim AI-Ready Panel PC and Rugged Edge Solutions at Embedded World 2025

- All Events News