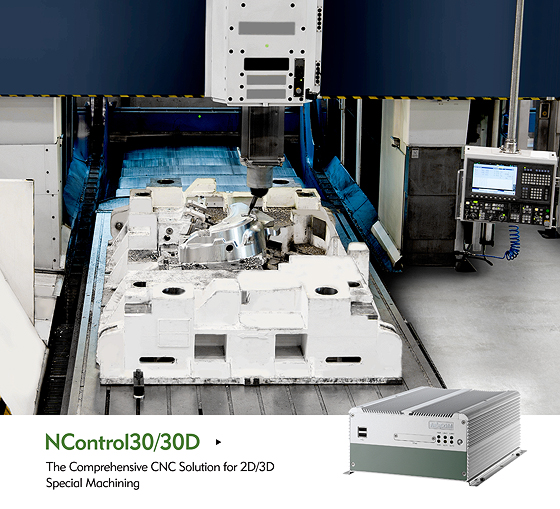

MECHATROLINK-III Certified NControl 30 Ensures Precise Control of Machine Automation

NEXCOM MECHATROLINK-III-certified NControl 30 holds machine automation to a high standard, yielding superior quality output of CNC machining. The PC-based CNC controller NControl 30 brings machine builders the openness of PC architecture, high-speed highly-reliable control of MECHATROLINK-III, and flexibility in machine development. Meticulous to details and precise in execution, the NControl 30 manages with ease the complexity and sophistication of 5-axis CNC machining, reinvigorating machine automation at full throttle.

As a high performance PC-based CNC controller, the NControl 30 supports advanced CNC functions to produce a smooth surface finish. With built-in functions such as tool center point (TCP) and look ahead planning and support for function expansion, the NControl 30 can equip 5-axis CNC machines and turning centers with all the dexterity required of 3D high-speed multi-channel machining. The NControl 30 can not only run a wide variety of machining processes including laser cutting, wood working, lathing, milling, and engraving; it can also consolidate auxiliary functions as supplements to CNC machines.

With quality coming first and foremost in manufacturers’ mind, the NControl 30 has acquired MECHATROLINK-III compliance verification to keep CNC machines operating to stringent requirements. Taking advantage of error detection and noise resistance features of MECHATROLINK-III, the NControl 30 can ensure control commands are delivered accurately to slave drives and I/Os. The CNC controller can synchronize and coordinate all slave devices, enabling fluent movements of all axes. In addition to MECHATROLINK-III, the NControl 30 is also available with EtherCAT master which is suited to large-scale machining processes.

As CNC functions differ significantly from application to application, the NControl 30 offers flexible CNC design with a pre-installed Windows-based programming development tool 4CONTROL and HMI programming tool WinNBI. Machine builders can modify built-in CNC functions, redeveloping application-specific features to demonstrate their core competence; or build customized CNC HMI to further differentiate the CNN machine from competitors. NEXCOM also offers the dual-OS option with the NControl 30D, enabling CNC machines to run computer-aided design tool and more.

Main Features

- Support 2D½ & 3D CNC machining

- Support MECHATROLINK-III and EtherCAT protocols

- Support G/M code

- Support tool center point (TCP)

- TCP with high speed machining

- Look ahead speed planning (up to 1024 blocks)

- High speed machining with polynomial interpolation

- Support multiple CNC channels

- Up to 24 channels can be customized

Ordering Information

CNC Controller

NControl30

3D CNC controller for machining and turning center with single-OS support

NControl30D

3D CNC controller and HMI for machining and turning center with dual-OS support

MECHATROLINK-III Servo Drive

Yaskawa Sigma V SD Series

Optional Accessories

C-101 Coupler

OPENrio EtherCAT bus-coupler

E-101 Module

OPENrio 16 digital input block

E-201 Module

OPENrio 16 digital output block

E-202 Module

OPENrio 4 x 2A digital output block

E-501 Module

OPENrio 2 analog input and 2 analog output block

- Related Links:

- NexAIoT Tech Day – Digitalization and Safety Robots Innovate Green Manufacturing

- NexCOBOT’s SRB, Your Ultimate UR+ Robot Gateway Integrator

- Browse Other News:

- Neu-X102-N50 Powers Automated Garment Management in Hospitals

- NEXCOM Presents Full Edge and AI Portfolio at GITEX Global 2025

- All Products News